0086-18695891045

Time : 2024-10-14

In recent years, the field of overhead crane has experienced significant technological advancements. These innovations are designed to improve efficiency, safety and sustainability, making overhead crane more intelligent and versatile in various industrial applications. Here are a few key areas of technological innovation:

1.Automation and intelligent control

One of the most transformative changes in overhead crane is the introduction of automation and intelligent control systems. Modern overhead crane are equipped with advanced sensors and software that enable autonomous or semi-autonomous operation, enabling precise movement and reducing human error. Through the integration of the Internet of Things (IoT), crane can provide data on real-time performance, usage patterns and maintenance needs, significantly reducing downtime.

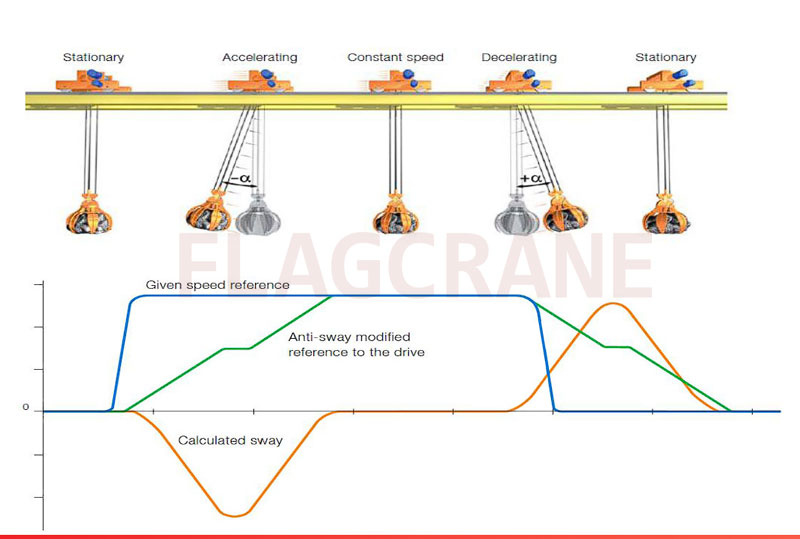

For example, smart crane are equipped with remote monitoring systems that allow operators to operate from a distance, ensuring safe operations in hazardous environments. Automatic features like anti-sway control also help maintain stability when lifting heavy loads, even in difficult environments.

2.Energy-saving design

Sustainability has become an important concern and overhead crane are no exception. The application of energy-saving motors and regenerative braking technology enables the crane to recover energy during the braking process. The recovered energy can be used for other operations or fed back into the grid, thus reducing overall energy consumption.

Many overhead crane are now equipped with variable frequency drives (VFDs), allowing the crane to operate at different speeds, optimizing energy use based on load weight and operational needs.

3.Advanced security features

Safety is crucial in crane operation and innovative safety systems significantly reduce the risk of accidents. Modern overhead crane are equipped with anti-collision systems that detect nearby objects through sensors and stop operations if necessary. In addition, the crane also has an overload protection function to ensure that the load capacity is not exceeded and structural failure is avoided.

Additionally, proximity warning systems and real-time load monitoring increase operator awareness, reducing the likelihood of accidents due to human error or equipment failure.

4.Lightweight and durable materials

The use of advanced materials increases the structural efficiency of overhead crane. The application of high-strength lightweight materials, such as carbon fiber composites and advanced steel alloys, allows manufacturers to reduce the weight of crane without sacrificing strength, thereby reducing operating difficulty, reducing wear and extending service life.

5.Modular design and customization

Many manufacturers now produce overhead crane with modular designs, allowing for more flexible configurations and easier maintenance. The modular design allows the crane to be customized to specific industrial needs while remaining adaptable for future upgrades. This innovation also facilitates faster installation and reduces downtime for maintenance and repairs.

6.Digital twin technology

Digital twin technology is a cutting-edge innovation in crane technology. A digital twin is a virtual copy of a physical crane, allowing operators and engineers to simulate operations in real time. This technology helps with predictive maintenance, process optimization and even provides a risk-free environment for employee training to study how the crane performs under different conditions.

Conclusion Technical advances in overhead crane have driven improvements in efficiency, safety and environmental sustainability. As industry increasingly relies on automated and data-driven processes, the evolution of overhead crane will continue, providing ever more sophisticated solutions to the world’s material handling challenges.