0086-18695891045

Time : 2023-05-19

Crane pulleys are divided into single pulleys, double pulleys and multiple pulleys according to the number of wheels. According to the connection mode of the pulley and the hanging object, it can be divided into four types: hook type pulley, chain ring type pulley, ring type pulley and hanger type pulley.

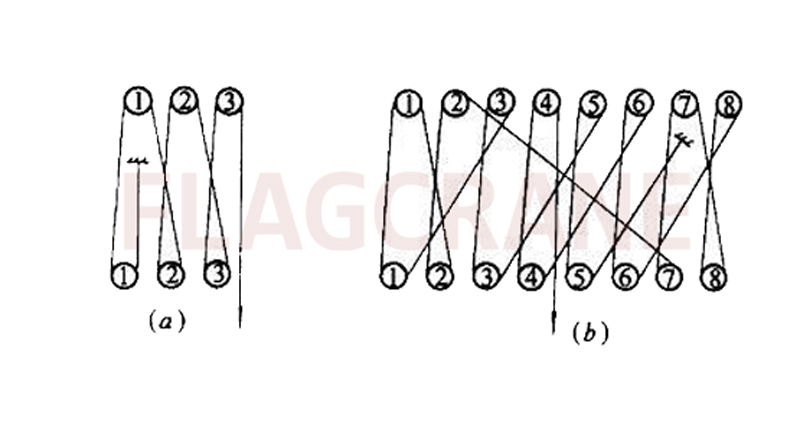

There are two main methods of winding steel wires for crane pulleys: "cross-cutting method and threading method"

a, Cross-cutting Method

When the number of pulleys in the pulley block is large, and a winch or crane is used for traction, the cross-cutting method can be used to improve the working conditions of the pulley block and reduce the pulling force. It can also ensure that the pulley block is evenly stressed and hoisted smoothly.

b, Threading Method

The threading method is a simple method of threading one end of the rope around the fixed pulley and the movable pulley one by one in sequence. According to the number of cranes or winches, a single end can be drawn out, or a double end can be drawn out with a non-rotating balance pulley. , The single-end straight-through method will increase the stress on each section of the rope, and the leading end will bear the largest force, which will easily cause the pulley to skew. Although this threading method has the advantages of simple and easy threading, it is suitable for pulley blocks with less than 4 pulleys. The double-tap threading method can not only prevent the pulley from skewing, but also work smoothly, reduce resistance, and speed up hoisting.

Flagcrane have a professional technical team, which can design and produce standard and non-standard crane hoist and spare parts. If there are other special requirements. it can be customize according to user needs and negotiate by both parties.